DIY Etude de Sol Instructions for Calculating Soakaways Drains in France

Ezy-Drain

While great advances have been made in wastewater technology, land drainage remains reliant on traditional techniques.

Now Klargester can offer the Ezy-Drain system, a revolutionary new product that redefines the method of dispersing water into soil.

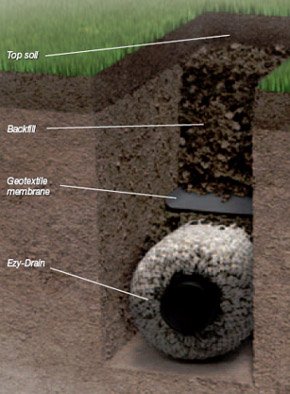

Utilising recycled synthetics packed around sectional tubes, the Ezy-Drain design offers a packaged solution to avoid the drawbacks of using loose quarried aggregates. The resultant benefits are an extremely lightweight system that can be rapidly installed without the need for specialist skills.

Applications

Treatment Plants and Septic Tanks: Ezy-Drain replaces the perforated pipework of a 'herring-bone' drainage field. Ezy-Drain's storage and flow charecteristics typically achieve 35% more surface area than natural aggregates, resulting in enhanced water treatment capabilities and a reduction in long term clogging.

Effluent Drainage: Ezy-Drain may replace traditional 'carrier' drainage from a treatment plant to discharge point.

Seasonal Soakaways: Ezy-Drain is ideal to install as a 'seasonal soakaway' flowing from a treatment plant. A seasonal soakaway allows infiltration of treated effluent where ground conditions permit or transfers effluent to an alternative discharge point when ground conditions are unfavourable.

|

| Trench excavated to site specific requirements arisings kept for re-use. |

|

3m Ezy-Drain sections are lightweight and easily handled. |

|

| Ezy-Drain sections are simply joined together using click fit connectors* Joints may be protected by the optional polystyrene collars or simply backfilled with as-dug material. | |

| Assembled Ezy-Drain system is then rolled into the dug trench. | |

| Arisings used to backfill to top of trench. |

(*not part of our supply but available from pipework stockists)

Benefits

- Speed of installation - up to 4 times faster than traditional methods.

- Lightweight increases handling capability and reduces Health & Safety hazards

- Single manpower installation - less labour and plant intensive

- Minimises site waste and disposal costs

- Flexibility removes need for boxes or chambers

- Ideal for sites with restricted access

- Higher water dispersion rate than traditional methods

- Reduced site impact - minimal reinstatement and clean up

Soil Porosity

To establish the overall length of a drain run required, a soil porosity test may be necessary. The following procedure should be adopted:

- Excavate a hole 300mm square by 300mm deep below the proposed invert level of the land drain.

- Fill hole with water to a depth of 300mm and allow to drain away overnight.

- Refill to a depth of 300mm and observe the time taken to drain from 75% full to 25% full level (i.e a depth of 150mm). Divide this time by 150mm. The answer gives the average time in seconds (Vp) required for the water to drop 1mm.

Repeat this exercise two more times with at least two trial holes. Calculate the average time.

By reference to the table below, the length of drain run required for various capacity tanks may be established.

Drainage field disposal should only be used on test values (Vp) between 12 and 100. Where a Vp value falls outside these limits, our technical team can advise.

Soil Porosity Test Data

Time taken to fall 150mm (mins) |

Equivalent value of Vp in sec/mm |

Overall length of drain run required (m) |

|||||

2800 litres (4 persons) |

3800 litres (10 persons) |

4600 litres (14 persons) |

6000 litres (22 persons) |

7500 litres (30 persons) |

9000 litres (38 persons) |

||

| 20 | 8 | 18 | 44 | 62 | 98 | 133 | 169 |

| 30 | 12 | 27 | 67 | 93 | 147 | 200 | 253 |

| 40 | 16 | 36 | 89 | 124 | 196 | 267 | 338 |

| 60 | 24 | 53 | 133 | 187 | 293 | 400 | 507 |

| 120 | 48 | 107 | 267 | 373 | 587 | 800 | 1013 |

| 180 | 72 | 160 | 400 | 560 | 880 | 1200 | 1520 |

The table indicates typical meterage for domestic septic tank applications, assuming a trench width of 450mm. Approximately 20% less drainage is required for Sewage Treatment Plants as treated effluent is of a higher standard. For other applications and further information, please consult Klargester.

Design The Ezy-Drain comprises of sections of twin wall perforated plastic pipe, surrounded by a synthetic aggregate, wrapped in polyethylene netting. Each 3-metre section is simply joined together by the use of click-fit connectors, protected by a preformed collar. The synthentic aggregate is manufactured from recycled expanded polystyrene, engineered to deliver optimum performance while consistently retaining its form. Delivery & Installation Ezy-Drain is entirely prefabricated and delivered in 3-metre sections directly to site. Installation can be performed by a single person without the need for aggregate, with trenches only requiring backfilling prior to immediate operation.

|

|