Fuel, Petrol, Oil Interceptors, Bypass Separators

Introduction:

Note that throughout this section the term ‘separator’ is used instead of the term ’interceptor’.

Surface water drains normally discharge to a watercourse or indirectly into underground waters (groundwater) via a soakaway. Contamination of surface water by oil, chemicals or suspended solids can cause these discharges to have a serious impact on the receiving water.

Oil separators are installed on surface water drainage systems to protect receiving waters from pollution by oil, which may be present due to minor leaks from vehicles and plant, from accidental spillage or due to deliberate and illegal tipping into drains.

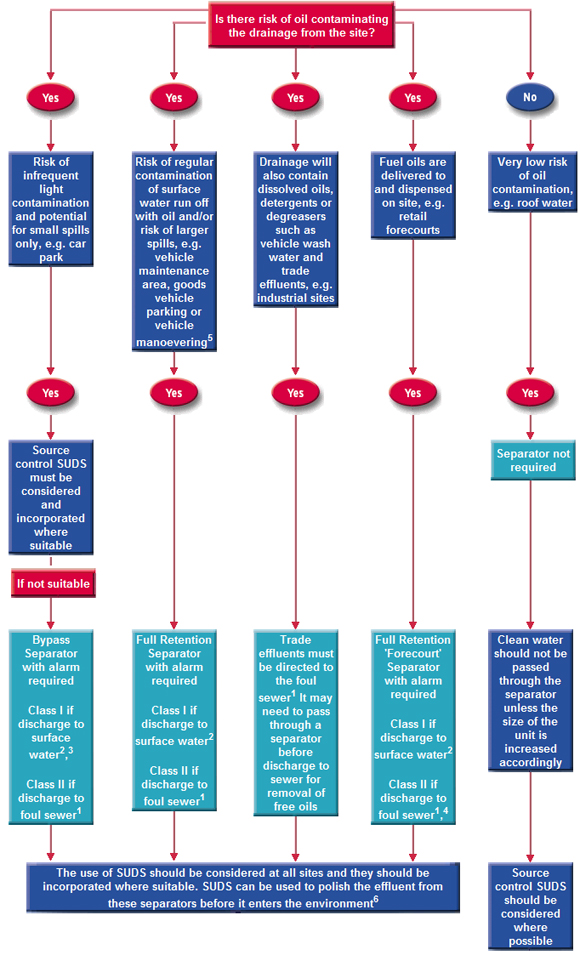

This chart gives guidance to aid selection of the appropriate type of oil separator for use in surface water drainage systems which discharge into rivers and soakaways.

For further detailed information, please consult the Environment Agency Pollution Prevention Guideline No. 3. (PPG 3) "Use and design of oil separators in surface water drainage systems” available from their website.

Klargester Environmental has a specialist team who provide technical assistance in selecting the appropriate Separator for your application.

Fuel/Oil Separator RangeFeatures and Benefits |

||

|

|

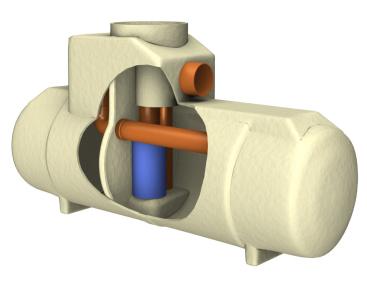

Full Retention Separator NS Range

|

|

|

|

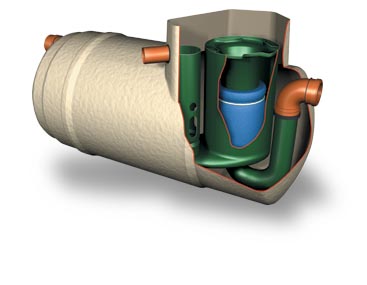

Bypass Separator NSBD Range

|

|

|

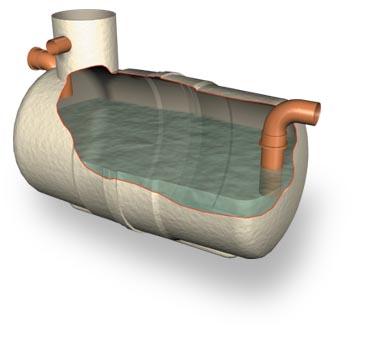

Washdown & Silt Separator

|

|

|

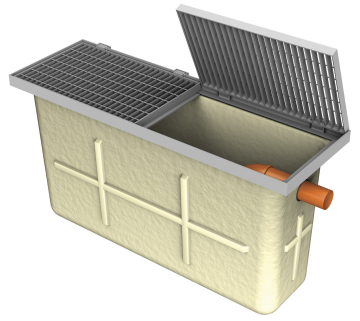

Silt Traps

|

|

|

Alarm SystemsBritish European Standard BS EN 858-1 and Environment Agency Pollution Prevention Guideline PPG3 requires that all separators are to be fitted with an oil level alarm system and that it should be installed and calibrated by a suitably qualified technician so that it will respond to an alarm condition when the separator requires emptying.

|

|